This is an antique German Junghans time and strike spring driven clock made in the style of a Vienna Regulator. It came to me as a box of parts. To some a box of clock parts and pieces is discouraging but to me it is a challenge.

Part II of a three part series on my newly acquired Junghans Crispi wall clock.

This is Part II of a three part series on my newly acquired Junghans Crispi wall clock. In Part I described the circumstances by which I came across this clock and it’s incredible story as a survivor of the Halifax Explosion of Dec 6, 1917.

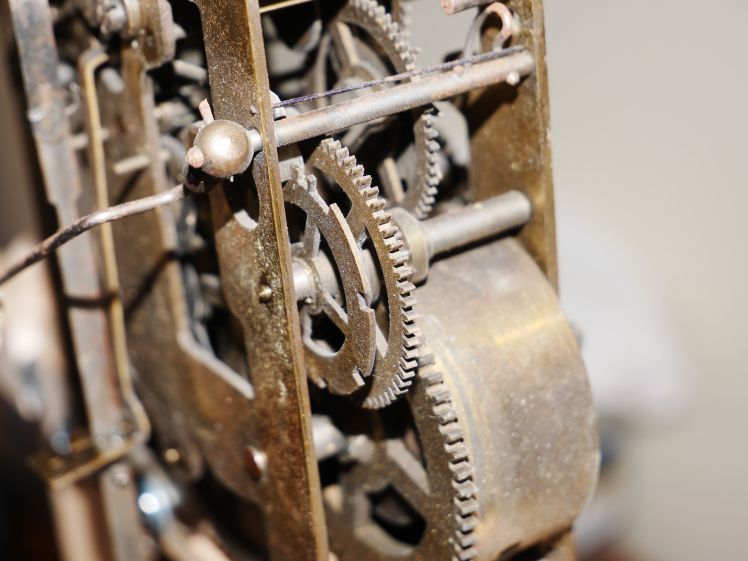

This is a German count-wheel strike typically found in the lower lines of Mauthe, HAC and similar clocks. It is an open plate “bread and butter” movement, not of the highest of quality but well built and reliable. The count wheel is located to the rear between the plates and the mainsprings are enclosed in open barrels. There are no helper springs to worry about and all of the wheels are located in the centre and the upper side of the movement.

As you can see in the next two photos the movement was very dirty and I accepted the risk of running it for a day to see what issues might arise. I gave the pivots holes plenty of oil to mitigate any additional wear. What I found was a sticky hammer assembly that would malfunction intermittently which I attributed to dirt and grime buildup, otherwise the movement ran very well after not having run for 100 years. Imagine all that kinetic energy stored in the springs since 1917.

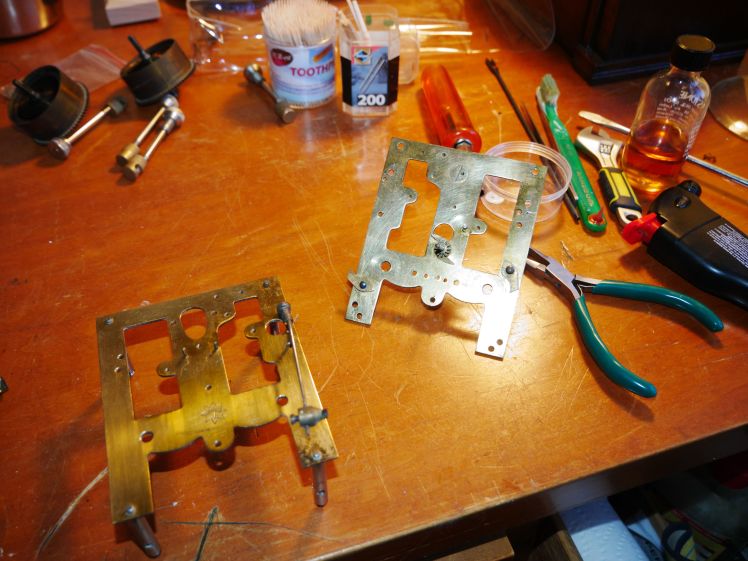

The movement is relatively easy to re-assemble but I had to install the lower centre wheel, the spring barrels and the centre cannon together with the top plate and then slide the gears in between the plates. Fortunately this process is not as difficult as it sounds but very different than laying the top plate right over the gears as you would in an American movement.

I gave the pivots holes plenty of oil in the testing phase to mitigate any additional wear

I found everything within acceptable limits and decided that bushing work was not required

The accumulated grime of 100+ years came off following the ultrasonic cleaning. In fact I have never seen the ultrasonic solution so dirty. The plates cleaned up very well and I gave them an additional polishing with Brasso. After the parts came out of the ultrasonic I tested the movement for any evidence of excessive play and found everything within acceptable limits and decided that bushing work was not required. The pivot holes were pegged and the pivots were polished.

There were no cracks or unusual issues with the mainsprings though I found it curious that they were very clean with no rust. There was also very little lubricant remaining. The springs are somewhat tired as you might expect but I think there is enough power remaining for a full cycle so I decided not to replace them at this point. I applied Keystone mainspring oil to the springs once I returned them to their barrels.

With the movement back together, it is time to adjust the strike side. The strike wheels must be set up correctly with respect to each other ensuring that the third (hammer lifting star wheel) and fourth wheels (the strike cam) align with he count wheel. The warning pin on the last wheel (which actually protrudes from the plate) has to be high enough for sufficient rotation. In order to count the strikes properly this relationship must be right. Unfortunately, I can never get this correct the first time.

The servicing of the movement is not without headaches, however.

The servicing of the movement is not without headaches, however. I bent a pivot on the warning wheel which I managed to successfully straighten out. The hammer arbor paddle was barely touching the star wheel and while trying to adjust it, I accidentally snapped it off along with the retaining spring. Although the clock will go though the strike sequence the gong will obviously not sound. I don’t have the tools to put in a new paddle so I will have to get that attended to somehow. I managed to correctly adjust the strike side but the clock mysteriously stops after about an hour or so. Something is definitely amiss and more investigation is required.

I have had more success with the case restoration that you will read about in Part III. In the meantime I have to constantly remind myself that this movement has not been running in 100 years!

It’s an awesome post in support of all the web visitors; they will obtain advantage from it I am

sure.

LikeLike

Thanks for coming to my blog

LikeLike

A person essentially help to make critically posts I’d state.

That is the first time I frequented your web page and

so far? I amazed with the analysis you made to make this particular

submit incredible. Great process!

LikeLike

Thanks for coming to my blog

LikeLike